Discover the advantages of the engineering and shipping service for pre-cut and pre-processed components and materials, or KITTING, provided by Global Composites.

Global Composites opens up a universe of possibilities where innovation meets excellence. We seek to offer services that make our clients’ day-to-day life easier, which is why we are proud to be leaders in transforming ideas into tangible realities such as the KITTING service.

Composite materials combine strength and versatility to ensure the future of multiple industries such as the chemical, railway or naval. For all of them, Global Composites wants to be the architect of real solutions.

We would like to tell you more about the engineering and delivery service for pre-cut and pre-processed components and materials, or KITTING.

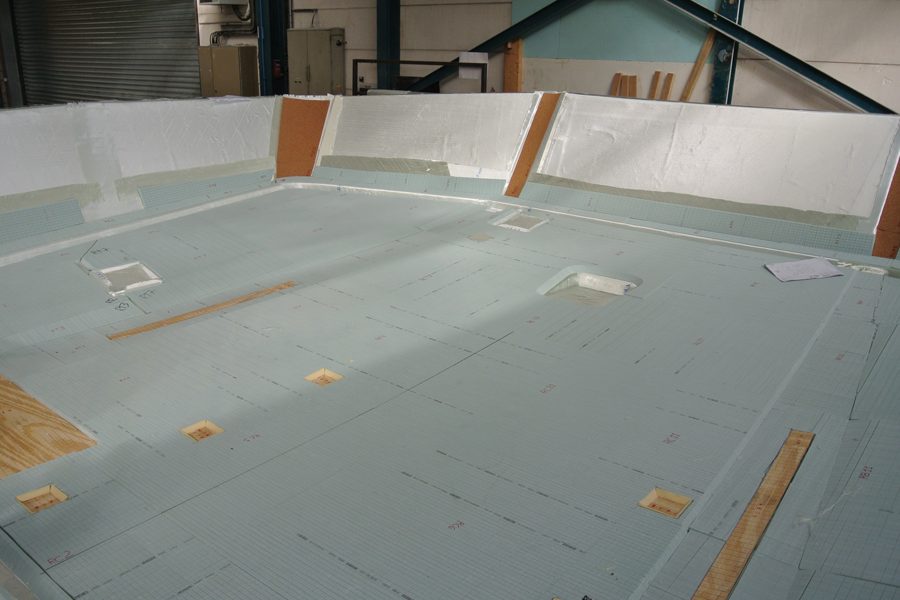

To complete the KITTING service, an advanced CAD study of the geometry of the part and the properties of the materials to be worked on is carried out, in order to process the materials in a second stage using CNC machining and cutting technology, capable of transforming materials such as glass fibres and infusion consumables, as well as PVC, PET, PUR, Balsa, etc. cores, into KITS that simplify their subsequent processing to the maximum. When the operator opens the corresponding KIT, he uses the products in the same order in which they are needed in the mould.

To manufacture the core KITS, state-of-the-art 5-axis CNC cutting and milling equipment is used to obtain high-precision results.

The complete KITTING service for fabrics such as glass or carbon fibres is structured in different stages, the first being the customised design, for the subsequent cutting, stacking and joining of layers with the highest precision and optimisation of shapes and patterns. The distribution is provided in KITS ready to be used in industrial manufacturing processes of composite materials.

As for the vacuum KITS, these are developed under laser positioning and glued in position and are provided by Global Composites with all the necessary elements such as profiles, connectors, sealing barrier, resin flow meshes, peel ply or reinforced plastic adjusting to the mould shapes. The kits are delivered rolled ready to be placed in the mould. What does this achieve? Reduce cycle time, improve storage and ease of handling.

Opting for this type of service is not simply a choice, it is a journey towards efficiency, sustainability and value for money:

- Production time is reduced by up to 60%.

- 0% waste generation.

- Reduction of materials used as a result of CAD development.

- High quality and improved finishes in infusion processes.

Do you want to distinguish yourself between those who strive for excellence and those who achieve it? When looking to the future, it is clear that innovation and quality are immovable pillars in the construction of sustainable and efficient solutions.

By choosing our services, you not only benefit from the latest technology and expertise that characterises us as Global Composites, you also join a true commitment to a possible future for all.